IKEA RÅTTA- Extra Thrifty Mouse

An ultra thrifty computer mouse for IKEA*, exploring how to save money in mass production with simple moulding and standardised components.

So many personal projects are fantastical when it comes to cost and feasibility. I wanted a way to explore manufacturability and some surfacing with something cheap and dirty, introducing IKEA Råtta!

Client: Personal

Location: Göteborg/Varberg, Sweden

Year: 2025

Role: The lot

How to make it cheap?

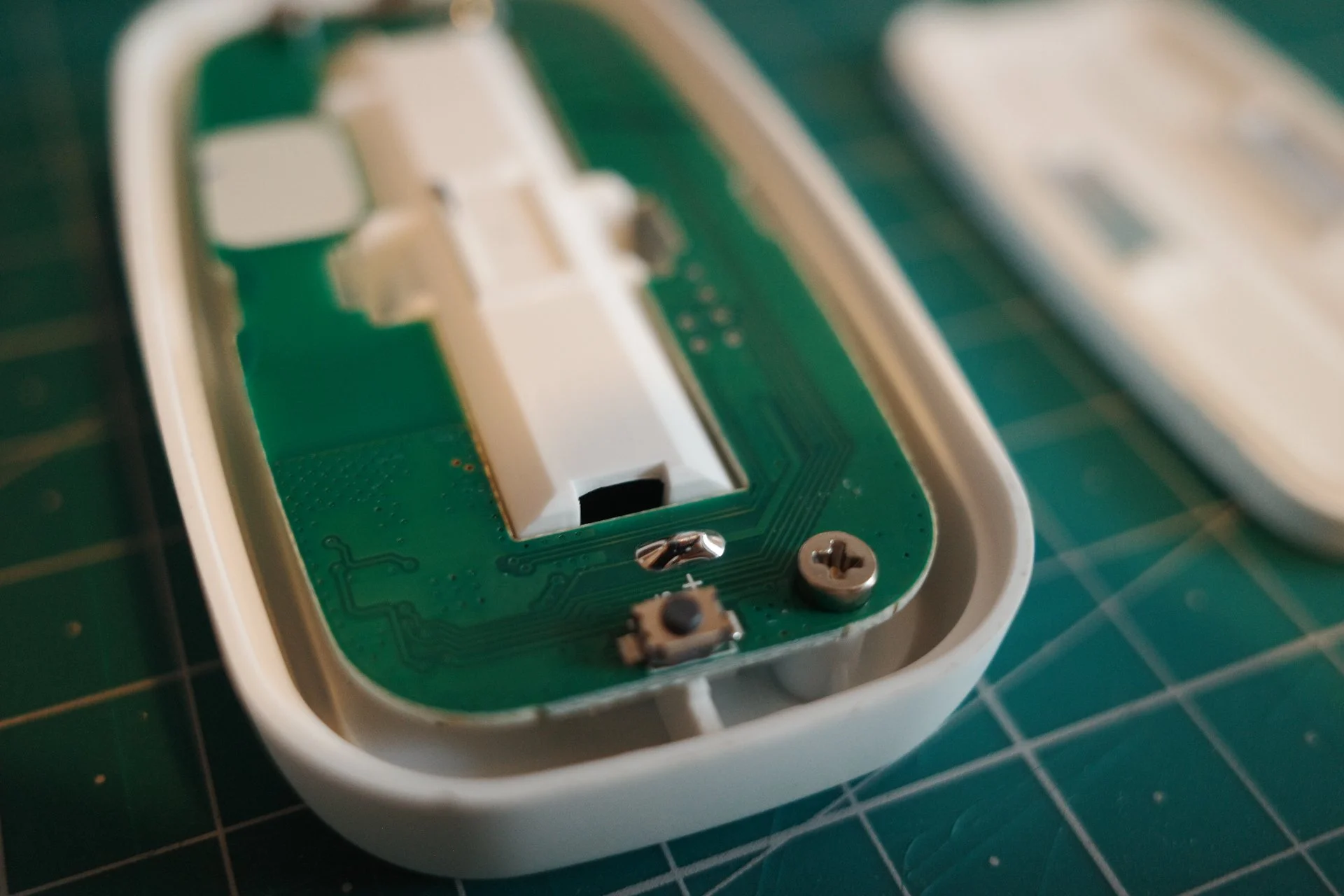

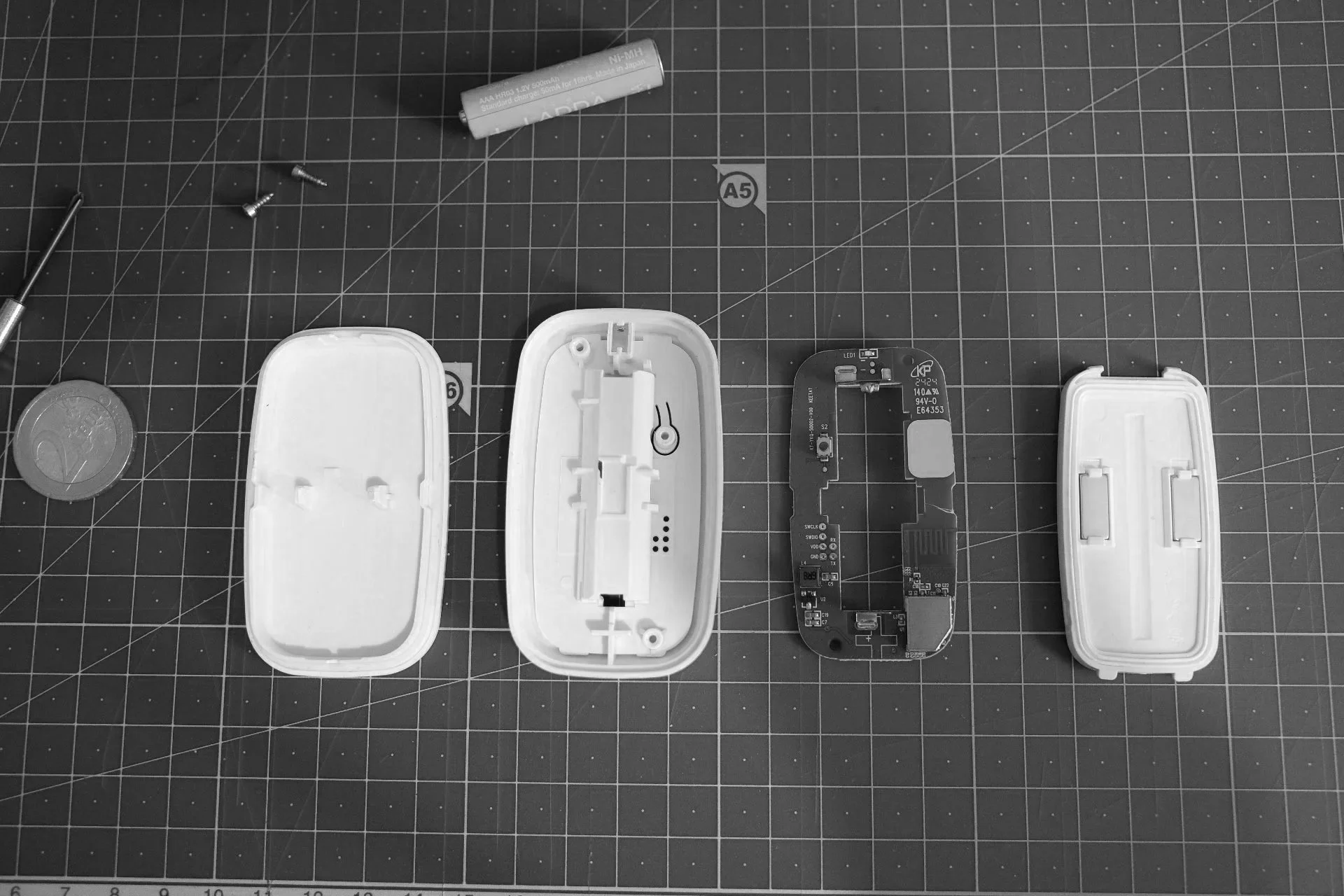

I was initially inspired by this little wireless controller IKEA sells for their smart home products.

It’s a masterclass in low cost manufacturing: chunky split lines, button towers, exposed clip fastenings, but with a focus on saving the polish for the more consumer-facing side. I especially liked the in-molded connection button.

My aim was to emulate this vibe in the mouse design.

Design Inspiration

The initial inspiration was the controller, but I also need to draw on some extra inspiration for the mousey elements and extra insertion on the vibe I wanted to evoke.

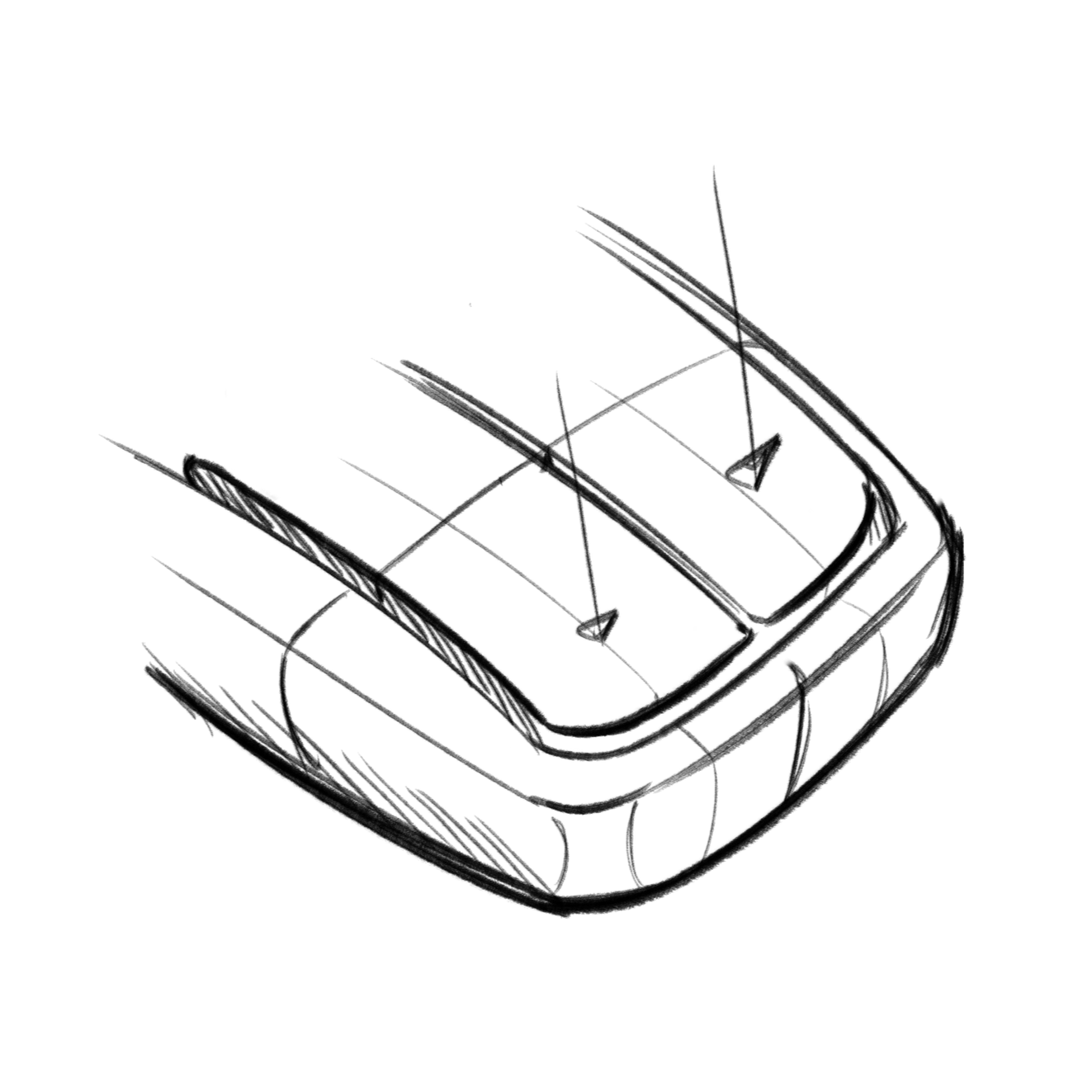

Finding and surfacing a form

The form wasn’t vitally important to the goal of the project, other than that it should feel comfortable in the hand and “Ikea-y”: clean, simple, injection moulded, a 95% good-enough kind of mouse with a friendly, ergonomic, slightly blobby feel.

The science art of surfacing

The first surfacing method I used is a Rhino technique called the “trimmed corner.” It cuts a three-sided surface on two sides to make four sides.

However, this approach didn’t work well in Fusion, making the surface uneven and causing unwanted sagging.

The second method used a lofted surface from an existing patch, then trimming with an isocurve to create a cleaner four-sided hole. Although there's a small three-sided shape at the tip, its four-sided origin gives us smoother reference surfaces.

The Zebra and curve map showed this, with any rougher surfacing pushed to the area where the body splitline will break the form anyway.

Time to split it up…

A crossroads in cost saving…

After I achieved a nice surface I started to carve up the form into parts, and this introduced a dilemma- How should the buttons be made?

Vs.

Most mice have a separate plastic plate for the clicky buttons, allowing the engineers to have more control over the click-tactility as well as helping reduce dust .

However, My intention was to have a single top shell with in-moulded buttons, but would this be realistic? is this a compromise too far? What should I do?

I made both…

Here’s the result!

The extra 50 kronor gets you a nicer click.

Making Mice, Saving Money

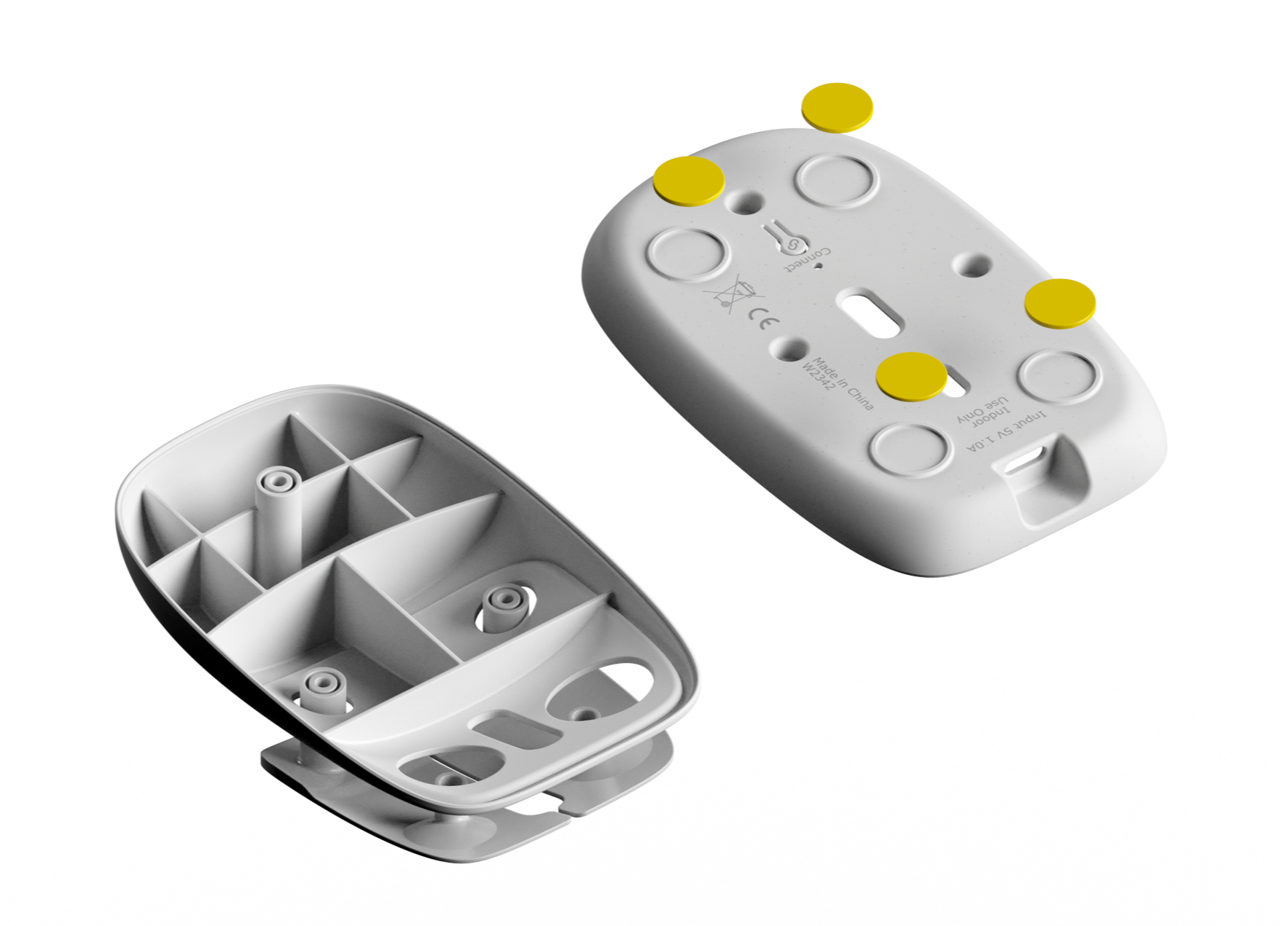

Parts like the teflon pads are standard sizes, meaning the BOM / production can order off-the-shelf parts that are quick to assemble… thrifty and simple!

The base steals the in-molded connect button, saving a whole custom tool. The screw bosses are exposed to allow for disassembly and cleaning, and are super deep to reduce shrinkage.

The top shell is single line of draw- no need for extra cores! And the screw bosses are hollowed out for reduced shrinkage on the consumer-facing exterior.

For the “Basic” model, all of the top shell is moulded in a single part with one line of draw- simple tooling saves money, and with exposed screws you can always use open it up and give it a clean!

Obligatory animated exploded view.

Reflections

This was a very fun project to try out, especially since most “personal projects” I see are often totally without limits.

It was interesting to impose some limits on what I could do with the design.

The hardest part of the project was staying realistic without much real-world data. Without access to moldflow info or design engineers, the design required many educated guesses from my previous design experience.

The most fun was finding the right form, something that played with the IKEA aesthetic and felt suitably thrifty, without entering the next rung down in quality to the anonymous Amazon OEM product.

And also the name. The original name was going to be “Husmus” (house-mouse) but I thought “Råtta” (rat) was a little more playful and on theme for the scrappy vibe I wanted to give to the product.