BraSatt 01- Autonomous Tree Planting

Award winning autonomous tree planting robot for Södra Skogsägarna, with a focus on expression, resilience, and ease of manufacture.

My role involved creating a visual expression, developing it through CAD, and visualising the result.

Client: Södra Skogsägarna

Location: Göteborg/Varberg, Sweden

Year: 2024

Role: Industrial Design, Visualisation

Context

Current tree re-planting requires heavy labour with low survival rates for the saplings.

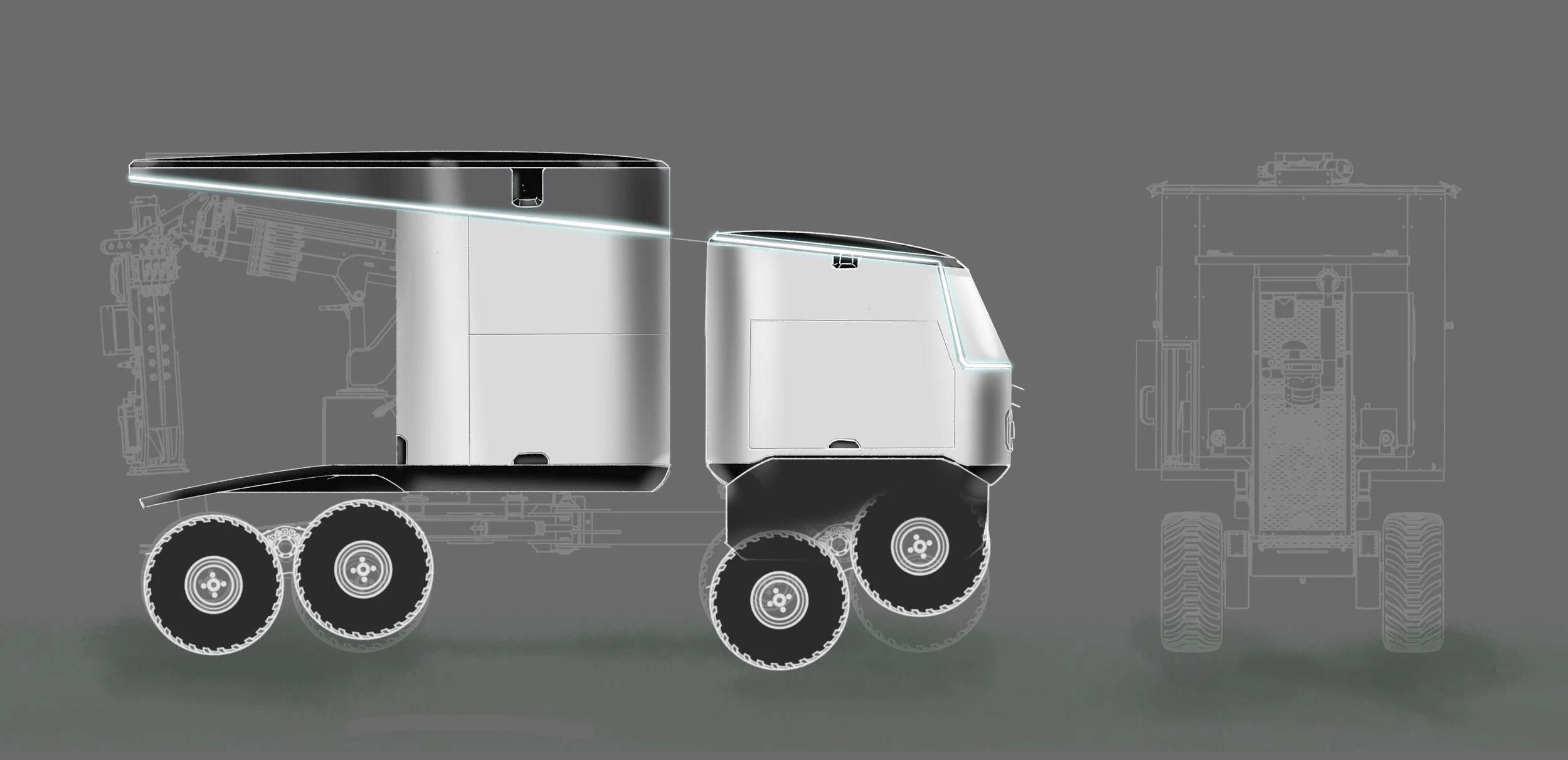

BraSatt01 is the first step towards automated, data rich planting, with the aim to raise sapling survival to over 90% and allowing workers to focus on digital preparation.

The Vision

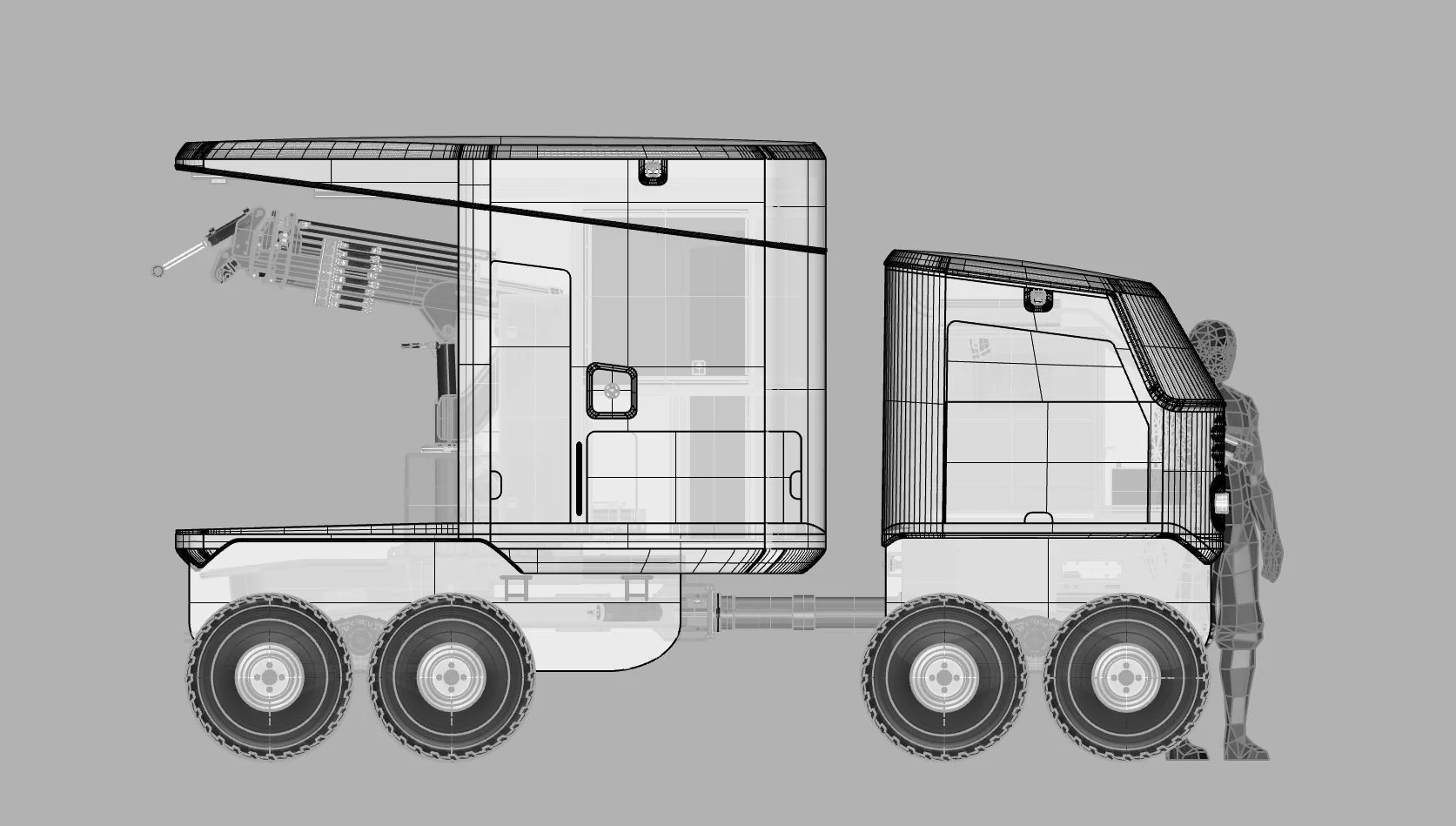

BraSatt01 imagines a future in which digital mapping and self driving technology enables more efficient tree planting a way that is gentler to the ground and ensures saplings are placed in the best possible soil.

My role within this project was to give form to the first prototype, but how should this new machine look?

Challenges

Rugged, Grounded, Directional

Could the design feel stable and rugged enough to survive all kinds of outdoor challenges, and directional, without feeling too fast?

A Collegate Feeling

This machine would work together with forestry workers, it should feel friendly, but not too cutesy.

Workshop Manufacture

This would be the first prototype, how can we make a futuristic design that still allows for workshop manufacturing?

Finding the form

Extracting Inspiration

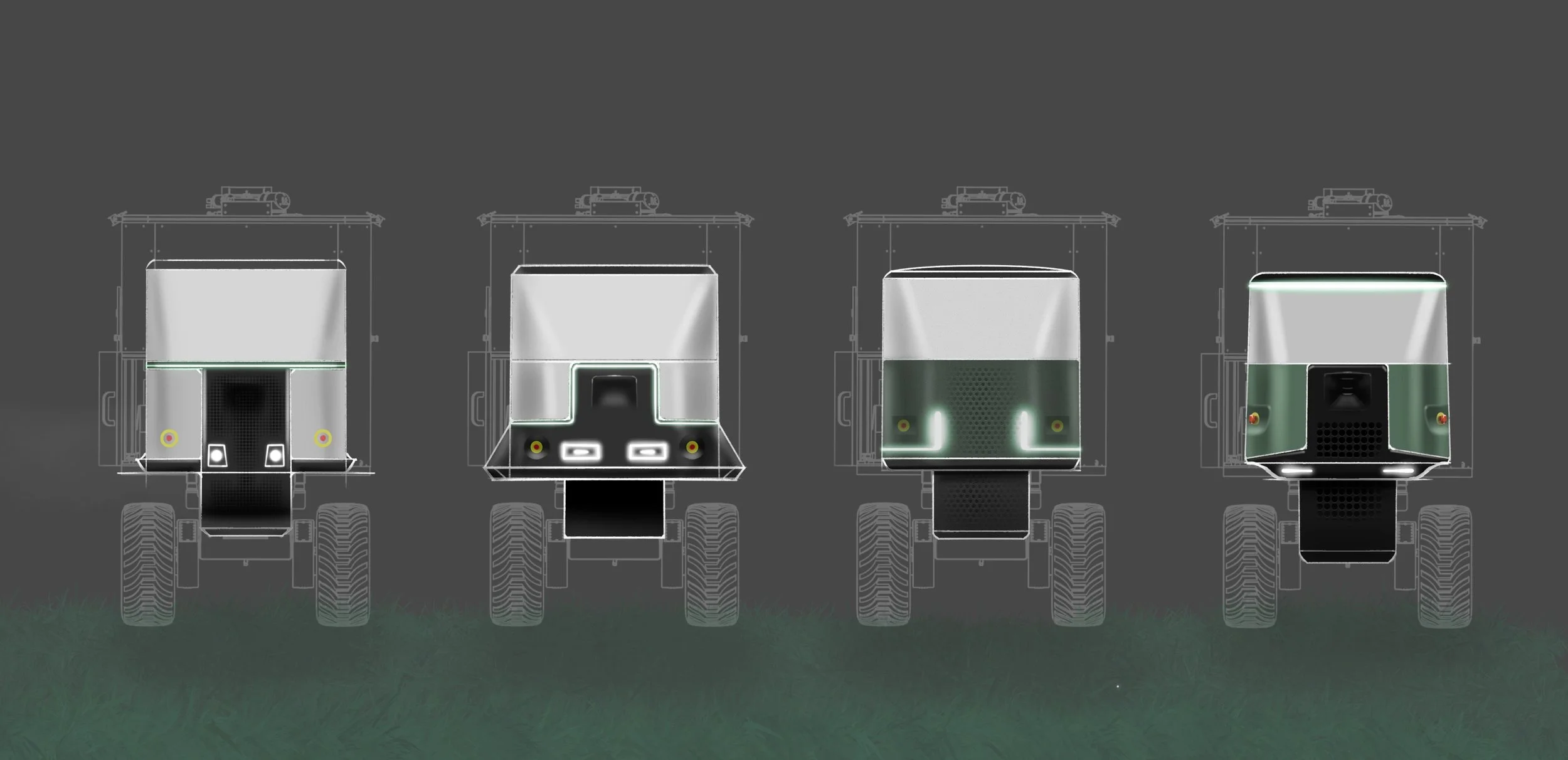

To build a tool palatte of forms and details to design with, I analysed products and concepts that had some element of Stability, Directionality, and Ruggedness.

This gave me the building blocks for more informed sketch ideation.

Look me in the eye

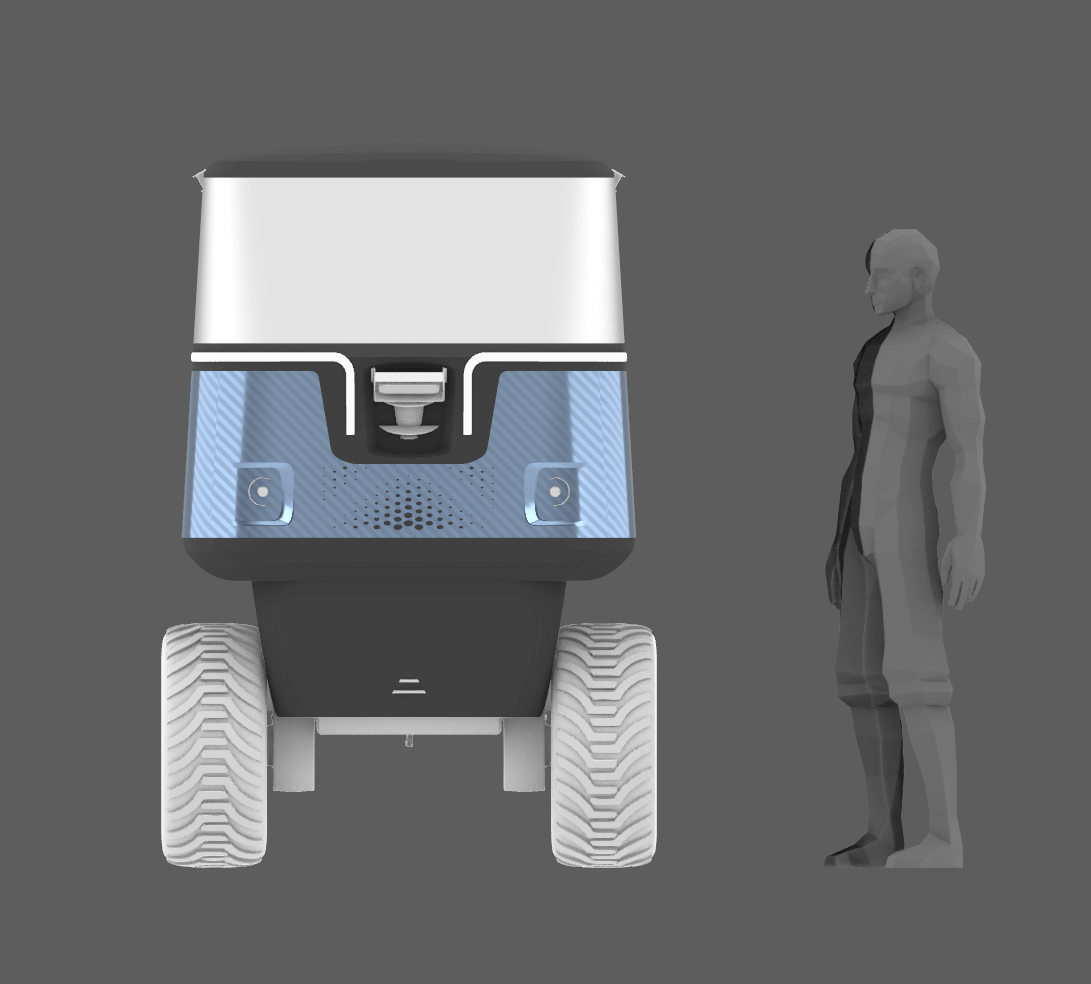

A key insight for me in this project was understanding the significance of the “eyes” of the vehicle.

The spacing and shape of these eyes decide have a huge influence on how we perceive it, with round and close giving cuddly, and distant and angular giving alien.

Developing the form

The strongest sketches were developed in Rhino to grasp 3D form and scale. This revealed how the “eyes” affected the design. The core design had two front emergency stops—adding more “eyes” caused confusion.

By integrating the LED headlights around the emergency stops gave harmony to the design.

Design for Manufacture

Using a mix of surfacing and solid body tools I transformed the vision into reality, working with simple plate materials and as close to curvature continuous plastic frames.

A little bit of CMF design also helped us explore colours and finishes.

This way I could build an assembly that could be easily translated into sheet metal and SLS plastic parts.

Result

The design was translated into reality, and now BraSatt01 is complete.

This prototype serves as a proof of concept for automated planting, and now testing will commence to see if we really can automate planting and increase survival.

In addition to a successful build, we also managed to secure a Red Dot Award: Best of the Best, for the design concept, a very happy addition to the project!

The Concept

Brasatt is more than the industrial design, and brings together mechanical, electronic, and environmental innovation into one concept.

This video explains how BraSatt works, from data to freshly planted tree.